H-20 (Ground Floor), Pocket-F, Sector-1,

Bawana (DSIDC), New Delhi - 110039, India

Fully Automatic Compression Testing Machine 3000 KN

Standard:-lS516, 14858-2000, EN 12390 4, ASTM C39, AASHTO T22

BRAND: ENTEK, MODEL NO. ET-CT-054

Fully Automatic Compression Testing Machine 3000 kN

Compression testing machine shall be fully automatic, controlled

through touch panel based electronic display system as well computer through

software. related to the size of the specimen and the expected load, and

capable of providing the rates of loading prescribed in IS 516.Compression

testing machine 3000 kN capacity with Servo Controlled based and automatic

pace rate controller. Machine includes the features given is lS 14858-2000

(reaffirmed 2005). In particular, the portable units, which are small in

dimensions, sturdy and light in weight, make quality control testing

possible in areas where commercial testing facilities are not available and

where the transportation of larger and much heavier machines would be

difficult. ENTEK Compression Testing Machines conform to IS: 14858(2000) and

calibrated with an accuracy of ± 1 % as per the requirement of

1828(Class1).

Loading Unit:-

The loading unit is of fully welded construction having across head, base and solid side plates. The hydraulic jack is fixed to the base. The platens of the machine are hardened, ground and polished. The upper platen is provided with self-aligning action. To facilitate testing of various size specimens, suitable sized spacers are provided.

Loading Unit:-

The loading unit is of fully welded construction having across head, base and solid side plates. The hydraulic jack is fixed to the base. The platens of the machine are hardened, ground and polished. The upper platen is provided with self-aligning action. To facilitate testing of various size specimens, suitable sized spacers are provided.

Technical Specifications :

Set test parameters including load rate:

This machine having the provision for automatically turning the pump ON and OFF, controlling the set pace rate and switching the machine off under predetermined conditions. Machine having inbuilt intelligent pace rate controller. It is having a full three term proportional integral derivative controller continuously calculating an error value and controls the loading on the rock specimen using a high torque Stepper Motor and driver sets. The loading frame is a fully welded construction with a top crosshead, base and solid side walls with the precision ground hydraulic piston fixed to the base, one lower platen and one top platen with self-aligning action. The Pump control facilitated through PID controlled EDI. Pace rates parameters can be set digitally and cannot be regulated manually. Machine able to operate as standalone with digital indicator unit as well with dedicated data management and analysis software installed in a desktop PC or laptop.

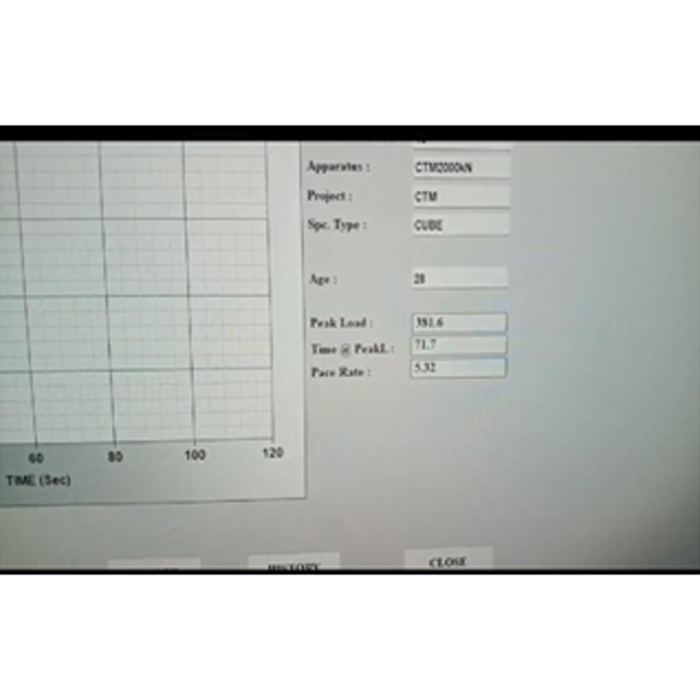

Peak load, Peak Stress,Unique record no displayed on the digital indicator, MS-Window based reputed make computer with compatible configuration to run the analysis software. Suitable for Testing above mentioned parameters for HQ, NQ & BQ size samples in Compression

| Model | ET-CT-054 |

| Capacity | 3000KN |

| Least Count | 0.1 KN |

| Load Accuracy: of the indicated load | ± 1% |

| Safety Over Load | 2% |

| Limit Switch, Safety Door | Provided |

| Load Resolution | 0.1 KN |

| Test Storage | 10000 Tests |

| Attachment | For Flexural & Splitting Tensile |

| Surface Hardness of Platen | 55 HRC |

| Material | Mild Steel |

| Lower Platen Dimension (Thickness x Diameter) | 50x320 mm |

| Upper Platen Dimension (Thickness x Diameter) | 60x320 mm |

| Maximum Vertical clearance between platens | 350mm |

| Maximum Horizontal clearance | 400 mm |

| Piston Diameter | 260±5 mm |

| Rated Pressure( Hydraulic Pump) | 20 |

| Maximum piston Stroke | 50 mm |

| Display Type | Microcontroller based 7” touch screen display |

| Automation Grade | Automatic |

| Pumping | Motorized |

| Pump Speed | Dual Speed |

| Motor | Servo Motor |

| Reading | Digital |

| Connectivity | USB 2.0, RS232, Wi-Fi, LAN |

| Auto stop after failure of specimen | Available, Machine stop after completion of test |

| Auto Release pressure after specimen Failure | Available |

| Calculation of result | Automatic |

| Holding Peak load | Yes |

| Computer operation software and data Acquisition software | Available |

| Displacement controlled operation | Available |

| Modulus of Elasticity Calculation | Available |

| Flexural attachment | Possible all calculations will be made automatically |

| Splitting Tensile Test | Possible, all calculations will be made automatically |

| Auto internal Calibration without proving ring | Available |

| Piston over travel safety cut off | Available |

| Over load safety cut off | Available |

| Shot circuit protection | Available |

| Multi Channel operation | 3 Channel operation possible, flexural and compression frame can be attached |

| Saving of records | Infinite records with Pen Drive |

| Pen drive slot | Inbuilt pen drive slot (saves reading in excel format (Record date-time, Sr. no. and peak load and N/mm2) |

| Real time graph | Available, on controller itself |

| Servo Type Voltage Stabilizer | 3kVA Single Phase |

| Over all Dimensions (LxWxH) | 840x635x1535mm |

| Total weight of machine Approx. | 1020 Kg |

Set test parameters including load rate:

This machine having the provision for automatically turning the pump ON and OFF, controlling the set pace rate and switching the machine off under predetermined conditions. Machine having inbuilt intelligent pace rate controller. It is having a full three term proportional integral derivative controller continuously calculating an error value and controls the loading on the rock specimen using a high torque Stepper Motor and driver sets. The loading frame is a fully welded construction with a top crosshead, base and solid side walls with the precision ground hydraulic piston fixed to the base, one lower platen and one top platen with self-aligning action. The Pump control facilitated through PID controlled EDI. Pace rates parameters can be set digitally and cannot be regulated manually. Machine able to operate as standalone with digital indicator unit as well with dedicated data management and analysis software installed in a desktop PC or laptop.

Peak load, Peak Stress,Unique record no displayed on the digital indicator, MS-Window based reputed make computer with compatible configuration to run the analysis software. Suitable for Testing above mentioned parameters for HQ, NQ & BQ size samples in Compression

- Press the start button

- Tighten the pressure valve

- The machine automatically : starts the rapid approach; switches to the test speed once the specimen comes into contact with the upper platen; automatically stops the motor upon specimen failure

- Save the test including data results

- The test execution conforming to standards can be easily proved

- Working on 220V, 50 Hz, single phase

- Dual stage pump assuring fast piston approach and precise test execution

- Test execution conforming to EN 12390 4, ASTM C39, AASHTO T22

- Controllable pace rate from 1 KN/Sec to 25 KN/Sec

- Auto stop after completion of each test

- Soft platen to specimen contracts and smooth load rate control from the very beginning of the ramp

- Servo motor driven machine

Frame:

- Four column high stiffness welded frame tested for stability

- Heavy duty spherical seat, allowing initial free alignment at the initial contact with the specimen and automatic jamming up to the end of test.

- Surface hardness of platen is 55 HRC, flatness tolerance 0.03mm. Traceable certificate of surface hardness available on request.

- Piston travel limit switch (Extra cost)

- Emergency stop button

- Servo motor driven machine

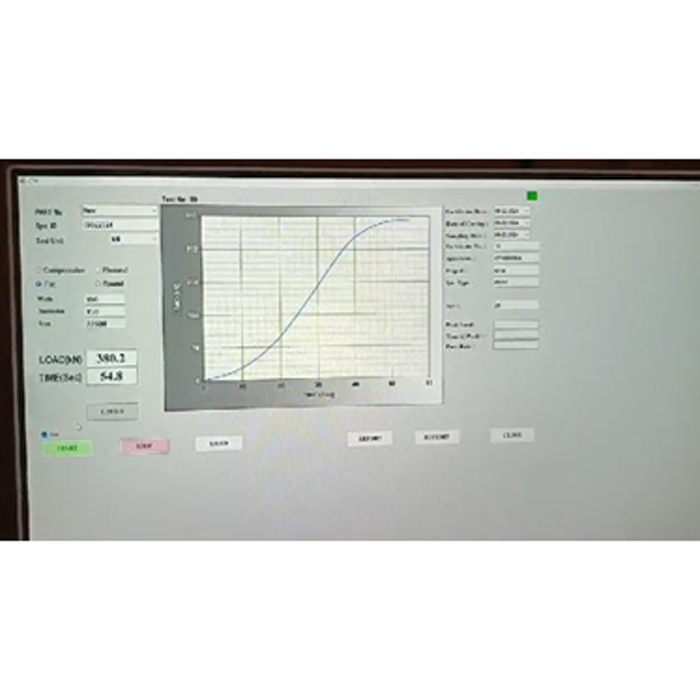

- Gives live online graph on the 7" touch screen

- User friendly large graphical display

- Displacement controlled machine also available (at extra cost)

- Saves 100 results in the 7" touch screen

- Inbuilt USB drive to save the date

Salient features of data manager PC software

Pumping Unit

ln addition to the above the machine should have the following features:-

- Two way communication i.e. machine operates from computer and from the touch screen controller both /(Stat, stop, save data and save graph)

- Results directly saved in excel file

- Graph also saved in excel file

- Capable to save customer name, other details of customer, ageing of cube mould, identification mark of the cube mould, date and time of testing

- Capable to print direct report from the computer

- Capable to select different test parameters like pace rate, sample size and area from the computer (software)

- Capable to select different type of tests, like flexural, CTM, aggregate crushing etc.

Pumping Unit

- Electrically operated pumping unit, The loads are measured on Digital Touch display Indicator which are calibrated against certified proving rings.

- Servo Controlled operated hydraulic power pack are of High speed design. The geared pump facilitates fast approach of the platens for daylight closure, thus eliminating the need for the lead screw.

- In the Electrically Operated Pumping Units, Digital Indicator switch-off the motor when the load approaches the maximum capacity of the Indicator, to avoid any over-loading. Relays are incorporated so that the motor does not restart on its own after a power breakdown.

- The electrically operated pumping units are provided with Variable Frequency Drive Motor to automatic adjust the desire pace rate.

- Microprocessor based electronic display - 7" touch Screen

heaving features:-

- Menu Driven Sample Detail

- Auto Calculation facility

- Peak Load

- Peak Stress

- Real-time graph in computer screen

- Test Record storing with Unique 1000 nos.

- Start, stop, pause, reset, load hold facility

- Data collecting USB

- Automatically transfers and saves test records and graphs in Desktop

- Each mode having independent calibration points

- Load Least Count 0.1 kN

- Hydraulic pump with Automatic rapid approach and precise oil flow controlAs per IS: 14858(2000), IS 516 and calibrated with an accuracy of ± 1% as per the requirement of 1828 (Class1)

- Micro data controller based models with automatic pace rate controllers

- Controllable pace rate from 1 KN/sec to 25KN/sec

- Automatic Pace rate servo controlling with an accuracy of 5% of Set Pace rate Facility to access data on PC

- Software shall be capable to plot graph real time data acquired for load Vs Displacement, Load vs Time, Stress Vs Strain.

- Load v/s Time, Load v/s displacementgraph generating automatic on Touch Display.

- Facility to log all test reports like Pace Rate and Peak load, Stress N/mm2 & Kg/cm2 on Touch Display 1.6 GHz, 64 bits Processor

- Suitable for operation on 220-240 V, 50 Hz, Three phase, AC Supply.

ln addition to the above the machine should have the following features:-

- Automatic pace rate control unit

- Pace deviation bar graph Load v/s Time

- Overload safety protection.

- Pre-defined machine capacities

- Flexible calibration point can be done on 10 points

- Peak load peak stress unique record number is displayed

- Data storage approx.10000 test result

- Connect PC to touch panel Wi-Fi/USB/RS232 port

- Store record can be viewed & print

- Peak stress calculation based on sample type & shape

- Password protection for system & calibration setup.

- Door Safety guard also provide.

- Multifunction touch screen panel set of pace rate

- One PC i7 processor with window 11, UPS and printer