H-20 (Ground Floor), Pocket-F, Sector-1,

Bawana (DSIDC), New Delhi - 110039, India

Compression & Flexural Strength

Compression Testing Machine (Channel Type Load Frame) Hand Operated

IS 516, BS 1881

Specification:

In these load frames "C" channels are used, they are welded at the top as well as bottom and with stand high loads. A hydraulic jack is fitted at centre of the base of the load frame, over which can be fitted lower platen and spacer block with the help of centering pin. A lead screw passes through the top of the frame. To the lower end of this lead screw is fixed the upper platen with spherical seat for self alignment. The platens are accurately machined, hardened and polished. The lower platen grooves to correctly place the specimen. Note: The platens are normally rectangular on shape, but no special request square platens or circular platens can be supplied at an extra cost.

Ranges: 50 kN to 2000 kN

Specification:

In these load frames "C" channels are used, they are welded at the top as well as bottom and with stand high loads. A hydraulic jack is fitted at centre of the base of the load frame, over which can be fitted lower platen and spacer block with the help of centering pin. A lead screw passes through the top of the frame. To the lower end of this lead screw is fixed the upper platen with spherical seat for self alignment. The platens are accurately machined, hardened and polished. The lower platen grooves to correctly place the specimen. Note: The platens are normally rectangular on shape, but no special request square platens or circular platens can be supplied at an extra cost.

Ranges: 50 kN to 2000 kN

Compression Testing Machine (Four Pillar)

Hand Cum Electrical Operated

Hand Cum Electrical Operated

IS 516, BS 1881

Specification:

The load frame is made up of high quality steel construction with a fixed. Upper lead carrying a ball seated platen. 4 pillars are fixed to the base and the top plate of the loading frame. The upper and lower plates are adjusted with the help of head screw on either side of the pillar. The ram dia of the machine varies from the requirements of the customer. The lower pattern are at the base of the frame above the ram and it is rectangular in shape. Sufficient clearance is provided between the platens to fit in the cylindrical/ cube moulds. Spacer provided to adjust cubes and cylinders. A 20 cm dia pressure gauge with maximum load induction pointer is fitted on the top panel and in turn is connected to the hydraulic pressure pipe. On the right hand a console is fitted within which the electrical motor is fitted alongwith its coupling which inturn is connected to the pumping unit. A slow / fast loading rate regulator fixed on the top of the console for adjusting the rate of loading. The machine is duly calibrated and passed after inspecting and analyzing it with a compression level indicator is provided as a dip stick.

Specification:

The load frame is made up of high quality steel construction with a fixed. Upper lead carrying a ball seated platen. 4 pillars are fixed to the base and the top plate of the loading frame. The upper and lower plates are adjusted with the help of head screw on either side of the pillar. The ram dia of the machine varies from the requirements of the customer. The lower pattern are at the base of the frame above the ram and it is rectangular in shape. Sufficient clearance is provided between the platens to fit in the cylindrical/ cube moulds. Spacer provided to adjust cubes and cylinders. A 20 cm dia pressure gauge with maximum load induction pointer is fitted on the top panel and in turn is connected to the hydraulic pressure pipe. On the right hand a console is fitted within which the electrical motor is fitted alongwith its coupling which inturn is connected to the pumping unit. A slow / fast loading rate regulator fixed on the top of the console for adjusting the rate of loading. The machine is duly calibrated and passed after inspecting and analyzing it with a compression level indicator is provided as a dip stick.

Flexure Testing Machine

IS 516, BS 1881

The Flexure Strength Testing are designed to test flexural strength of concrete beams. The design provide maximum rigidity throughout their working range. The load is applied by the downward movement of the piston. A spacer is for testing different size of beams. The load is indicated on a calibrated bourdon tube type load gauge of range: 0 - 100 kN x 0.5 kN (0- 10,000 kgf x 50 kgf). The load gauge is calibrated against National Council for Cement and Building Materials Certified Proving Ring.

Flexure Testing Machines

The Flexure Strength Testing are designed to test flexural strength of concrete beams. The design provide maximum rigidity throughout their working range. The load is applied by the downward movement of the piston. A spacer is for testing different size of beams. The load is indicated on a calibrated bourdon tube type load gauge of range: 0 - 100 kN x 0.5 kN (0- 10,000 kgf x 50 kgf). The load gauge is calibrated against National Council for Cement and Building Materials Certified Proving Ring.

Flexure Testing Machines

- Light weight, rugged high strength frame

- Double action hydraulic pump

- Self-aligning roller assembly

- Hydraulic jack provided with retraction spring

- For testing beams of 100 x 100 x 500mm and 150 x 150 x 700mm

- Conforms to IS 516, BS 1881 and ASTM C 78 Two Models are available.

Hand Operated Flexural Testing Machine 250 Kn

Specification:

- Ram Diameter (mm) : 82

- Ram Travel (mm) : 50

- Pressure Gauge Diameter (mm) : 200

- Pressure Gauge (in kN) : 100

- Least Count (in kN) : 0.5 Kn

- Maximum Pressure (Kgs. /cm) : 200

- Platen Diameter (mm) : Nil

- Horizontal Clearance (mm) : 210

- Vertical Day Light (mm) : 160(adj)

- Height Of Load Frame (mm) : 850

- Weight Of Load Frame (Kgs) : 150

- Lead Screw : Yes

- Specimen Size (can Be Tested) : 0

- Cube (mm) : Nil

- Cylinderical : Nil

- Flexural Test (size in mm ) : 100x100x500 , 150x150x700

Flexural Frame 100 Kn

ASTM C 293, ASTM C 496, ASTM C 78, EN 12390-5, EN 12390-6, EN 1338, EN 1340

Flexural frame for above machine connected to the automatic pump 100 kn capacity

General Properties:

The Entek Automatic range of 100 kn capacity flexure testing machines have been designed to meet The need for reliable and consistent testing of flexural test on standard concrete beams, transverse Test on kerbs and flagstones, indirect tensile tests on concrete and interlocking pavers. Entek flexural machines consist of their main part; frame. Each part has been designed to manufacture Machines with a high degree of mechanical stability and complies with EN 12390-5, EN 12390-6, EN 1338, EN 1340, ASTM C78, C293 and C496 by choosing suitable accessories.

Frame:

The versatile load frame is designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is welded steel fabrication carrying the ram fitted to the upper crosshead. All frames have a single acting down stroking ram with over travel switch protection to shut the machine down should maximum ram travel be reached. The return of the ram is done by dead weight to get maximum accuracy on the load measurement. The load cell is used for load measurements. All flexural frames have been designed to accept all the accessories for flexural and transverse tests. Both frames can be connected to any compression machine as a second frame.

Flexural frame for above machine connected to the automatic pump 100 kn capacity

General Properties:

The Entek Automatic range of 100 kn capacity flexure testing machines have been designed to meet The need for reliable and consistent testing of flexural test on standard concrete beams, transverse Test on kerbs and flagstones, indirect tensile tests on concrete and interlocking pavers. Entek flexural machines consist of their main part; frame. Each part has been designed to manufacture Machines with a high degree of mechanical stability and complies with EN 12390-5, EN 12390-6, EN 1338, EN 1340, ASTM C78, C293 and C496 by choosing suitable accessories.

Frame:

The versatile load frame is designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is welded steel fabrication carrying the ram fitted to the upper crosshead. All frames have a single acting down stroking ram with over travel switch protection to shut the machine down should maximum ram travel be reached. The return of the ram is done by dead weight to get maximum accuracy on the load measurement. The load cell is used for load measurements. All flexural frames have been designed to accept all the accessories for flexural and transverse tests. Both frames can be connected to any compression machine as a second frame.

Semi Automatic Compression Testing Machine

ASTM C39; AASHTO T22; ISO EN 7500, EN 12390-4

The Entek Semi-Automatic (Motorized) range of 2000 kN and 3000 kN capacity compression testing machines have been designed for reliable and consistent testing of a wide range of specimens. These compression testers are manufactured as a result of continuous research studies to upgrade the machines with the latest technologies to conform with the latest standards EN 12390-3, 12390-4, BS 1881 in terms of its technical properties taking into account the client requirements. These machines also meet the requirements of CE norms with respect to the health and safety of the operator. And their user-friendly design enable an inexperienced operator to perform the test.

The Entek Semi-Automatic (Motorized) range of 2000 kN and 3000 kN capacity compression testing machines have been designed for reliable and consistent testing of a wide range of specimens. These compression testers are manufactured as a result of continuous research studies to upgrade the machines with the latest technologies to conform with the latest standards EN 12390-3, 12390-4, BS 1881 in terms of its technical properties taking into account the client requirements. These machines also meet the requirements of CE norms with respect to the health and safety of the operator. And their user-friendly design enable an inexperienced operator to perform the test.

Automatic Compression Testing Machine 1000KN

Features:

- Conforming to Testing Procedures laid down in IS: 516/IS: 4031: Part 6: 1988/ASTM C39 for concrete specimen.

- Machine conforming to IS: 14858.

- Menu Driven Interface

- Facility to perform various operations such as TARE, PROGRAMMING, START, STOP Etc. from touch panel display

- Programmable rate of loading (Pace rate) and sample parameters (Shape, Dimension etc.) through touch panel display

- Standalone system to operate the machine (Start, stop and hold) without computer

- Microprocessor based touch panel graphic display to control the machine operation and display of data

- Fully automated operation to start, stop and hold loading with automatic pace rate control from 1-10 kN/sec..

- Automatic strength calculation and display

- Automatic pace rate control at preset value with pace deviation bar.

- On-Line display of Load and Peak load with recording of peak load along other sample details

- Peak stress calculation based on sample type, shape and dimensions

- Inching/fast lift operation to adjust gap between sample and upper platen.

- Safety limits for Over Load and Over Displacement ranges.

- Configurable Engineering Units for machine selection

- Storing of results in user defined file with sample parameter and other details

- Real time clock check to keep automatic track of the date, time and runs

- Test results can be stored in the electronic unit with unique record no. and can be retrieved and transferred to USB drive for printing

- Transmission of Data to computer through Ethernet/USB/RS232 Port. Supplied complete with two additional channel for Strain Gauges. Strain Gauges are not part of the supply. The complete system consists of Load Frame, Hydraulic Pumping Unit, Microprocessor based touch panel display and control system & various height spacers to accommodate different size specimen.

- Load Frame

- Capacity : 1000kN

- Max. Ram travel : 50 mm

- Day Light clearance : 340 mm

- Horizontal clearance : 350mm

- Size of platen : 256 mm

- Hydraulic Pumping System

- Hydraulic pumping system, housed in an elegant console for low noise, consists of multi plunger pump driven by a suitable servo motor operated on 220 V, Single Phase, 50 Hz.

- The pump gives a continuous non-pulsating oil flow to the ram of the loading frame.

- Pressure switch is provided

Fully Automatic Compression Testing Machine

Entek make CE certified fully automatic compression

testing machine 1000 kn / 2000 kn / 3000 kn capacity

with all distance platens for 150 mm cube/100 mm

cube 150 x 300 mm cylinders, software.

General properties:

The automatic range of 3000 kn capacity compression testing machines has been designed to meet the need for reliable and consistent testing of concrete samples.all Entek machines feature the complete automatic test cycle with a closed loop digital readout. Once the specimen parameters have been introduced, it is sufficient to press the start button to complete the test. Entek compression machines consist of their main parts: frame, power pack and data acquisition & control system. Each part has been designed to manufacture machines with a high degree of mechanical stability and complies to EN 12390-4, BS 1881 and ASTM C39 (with suitable platen set)

Frame:

The load frame is a welded steel fabrication carrying the ballseated upper platen. Positively located on the loading ram which is protected from debris by a cover, the lower platen is marked for the centering of cube and cylinder specimens. The dimensions of the frame allow the testing of concrete cylinders up to 320 mm long x 160 mm diameter; 100, 150 mm cubes. All machines are supplied complete with 30 mm, 50mm and 90 mm distance pieces. To test samples shorter than 150 mm extra distance pieces should be ordered. All machines are supplied with flexi glass front and rear removable safety doors. All frames have a single acting upstroking ram with over travel protection to stop the motor when the maximum platen travel be reached.

General properties:

The automatic range of 3000 kn capacity compression testing machines has been designed to meet the need for reliable and consistent testing of concrete samples.all Entek machines feature the complete automatic test cycle with a closed loop digital readout. Once the specimen parameters have been introduced, it is sufficient to press the start button to complete the test. Entek compression machines consist of their main parts: frame, power pack and data acquisition & control system. Each part has been designed to manufacture machines with a high degree of mechanical stability and complies to EN 12390-4, BS 1881 and ASTM C39 (with suitable platen set)

Frame:

The load frame is a welded steel fabrication carrying the ballseated upper platen. Positively located on the loading ram which is protected from debris by a cover, the lower platen is marked for the centering of cube and cylinder specimens. The dimensions of the frame allow the testing of concrete cylinders up to 320 mm long x 160 mm diameter; 100, 150 mm cubes. All machines are supplied complete with 30 mm, 50mm and 90 mm distance pieces. To test samples shorter than 150 mm extra distance pieces should be ordered. All machines are supplied with flexi glass front and rear removable safety doors. All frames have a single acting upstroking ram with over travel protection to stop the motor when the maximum platen travel be reached.

Compression And Flexural Testing Machines Splitting

Tensile Test Device

Tensile Test Device

Features:

- Splitting tensile test device For Ø150x300 mm and Ø160 x 320 mm

- Cylindrical specimens, ASTM/EN Distance piece For Ø100 x 200 mm, cylindrical specimens, EN

- Splitting tensile test device For 60-150 mm height x 220 mm

- Splitting tensile test device For 150x150 mm concrete cubes, EN

- Distance piece For 100x100 concrete cubes, EN

Hydraulic Jacks

Hydraulic Jacks have multipurpose utility, i.e. application of loads while engaged

in field investigation, determination of load carrying capacity of piles in the field,

tensioning of wires in pre-stressed structures, loading of members of any structure for

deformation characteristics etc. The jacks are supplied complete with manually operated

pumping units fitted with bourdon tube type load gauge and high pressure flexible hose

pipe. All the jacks have a piston travel of 50 mm and jacks upto 1000 kN capacity are

provided with retraction springs.

Note: Piston Travel upto 150 mm can be provided on request.

Note: Piston Travel upto 150 mm can be provided on request.

Digital Load Indicator

Features:

- Large alphanumeric LCD display with backlight

- 10 Segment bar graph for display of variation in Pace Rate

- Sample Area digitally settable

- Stress at Peak load calculated & displayed

- Peak/Normal mode selectable

- Buzzer alarm for peak detection in Peak Mode

- Relay output for load limit detection

- Digital tare provided

- Non-volatile memory for saving configuration

- RS-232 serial output for logging on PC

- Configuration lock at rear to prevent tampering

- Aesthetically designed front panel with membrane switches

Fully Automatic Compression Testing Machine

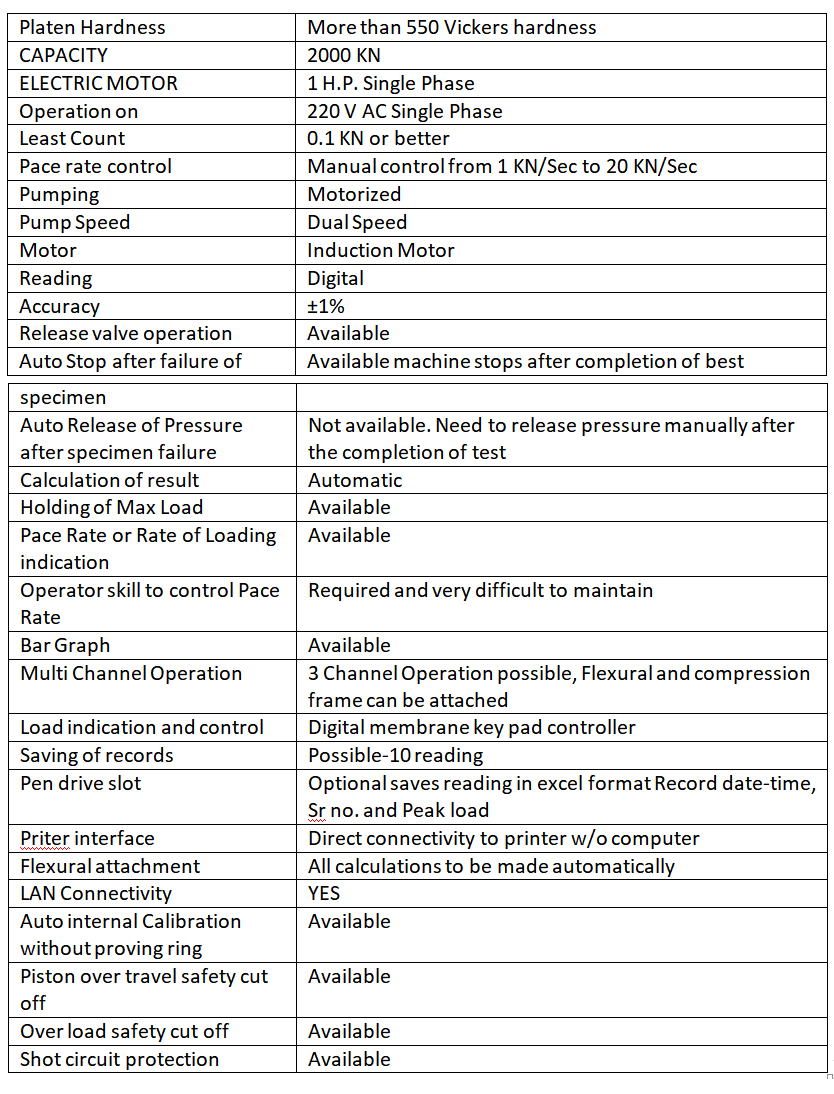

Brand- ENTEK , Model No.- ETK-CTM-2000KN

Standard:-lS516 (part 1/ Sex 1): 20021/516 (part 4):2018/IS 15658:2021 for concrete cubes, core & concrete paving block specimen.

Machine conforming to IS 14858-2000, EN 12390 4, ASTM C39, AASHTO T22

Fully Automatic Compression Testing Machine 2000 kN Compression testing machine shall be fully automatic, controlled through touch panel based electronic display system as well computer through software. related to the size of the specimen and the expected load, and capable of providing the rates of loading prescribed in IS 516.Compression testing machine 2000 kN capacity with Servo Controlled based and automatic pace rate controller. Machine includes the features given is lS 14858-2000 (reaffirmed 2005).

In particular, the portable units, which are small in dimensions, sturdy and light in weight, make quality control testing possible in areas where commercial testing facilities are not available and where the transportation of larger and much heavier machines would be difficult. ENTEK Compression Testing Machines conform to IS: 14858(2000) and calibrated with an accuracy of± 1 % as per the requirement of 1828(Class1).

Loading Frame Unit:-

The loading unit is of fully welded construction having top crosshead, base and solid side plates. The precession ground hydraulic piston is fixed to the base and the platens of the machine are hardened, ground and polished.

Front Cover provided as a protection to the operator while at the same time giving an unobstructive view of the specimen under test.

Hydraulic Pumping Unit:-

Digital Control Unit:-

Microprocessor based electronic display - 6” touch Screen with automatic pace rate heaving features:-

Standard:-lS516 (part 1/ Sex 1): 20021/516 (part 4):2018/IS 15658:2021 for concrete cubes, core & concrete paving block specimen.

Machine conforming to IS 14858-2000, EN 12390 4, ASTM C39, AASHTO T22

Fully Automatic Compression Testing Machine 2000 kN Compression testing machine shall be fully automatic, controlled through touch panel based electronic display system as well computer through software. related to the size of the specimen and the expected load, and capable of providing the rates of loading prescribed in IS 516.Compression testing machine 2000 kN capacity with Servo Controlled based and automatic pace rate controller. Machine includes the features given is lS 14858-2000 (reaffirmed 2005).

In particular, the portable units, which are small in dimensions, sturdy and light in weight, make quality control testing possible in areas where commercial testing facilities are not available and where the transportation of larger and much heavier machines would be difficult. ENTEK Compression Testing Machines conform to IS: 14858(2000) and calibrated with an accuracy of± 1 % as per the requirement of 1828(Class1).

Loading Frame Unit:-

The loading unit is of fully welded construction having top crosshead, base and solid side plates. The precession ground hydraulic piston is fixed to the base and the platens of the machine are hardened, ground and polished.

Front Cover provided as a protection to the operator while at the same time giving an unobstructive view of the specimen under test.

Hydraulic Pumping Unit:-

- Hydraulic pumping system, housed in an elegant console for low noise, consists of multi plunger pump driven by a suitable motor operated on 220-240 Volts AC, 50Hz, single phase.

- Pump gives a continuous non pulsating oil flow to the ram of the loading frame.

- Pressure switch is provided for additional safety against precise control over load.

- Release valve is also placed at a convenient location to release the load manually after sample failure if automatic system not working.

Digital Control Unit:-

- Manual control from 1 KN/Sec to 20 KN/Sec

- Control Chanel- Load/Stress

- Microprocessor based touch panel graphic display to control the machine operation and display of data.

- Real time display of load and peak load value with pace rate deviation bars.

- Real time display of load and peak load value with pace rate deviation bars.

- Inching/fast lift operation to self-aligning between sample and upper platen.

- Automatic strength calculation and display.

- Peak stress calculation based on sample type, shape and dimensions

- Storing of results in user defined file with sample parameter and other details

- Transfer of results sheet to USB drive for printing and further analysis.

- Safety Limits for over load and over load and over displacement ranges.

- 2% Overload facility to calibrate the machine upto full capacity.

- Multifunction keyboard with facility of start, stop, & reset.

Microprocessor based electronic display - 6” touch Screen with automatic pace rate heaving features:-

- Menu Driven Sample Detail

- Auto Calculation facility

- Sample selection facility

- Peak Load

- Peak Stress

- Over Load Safety Protection

- Over Displacement Safety Protection

- Real-time graph Load Vs Time, HMI Display

- Test Record storing up to10,000 nos.

- Start, stop, pause, reset

- Data collecting via USB