H-20 (Ground Floor), Pocket-F, Sector-1,

Bawana (DSIDC), New Delhi - 110039, India

Abrasion Testing

Los Angeles Abrasion Testing Machine

IS 2386 (PART IV) ASTM C 131, AASHTO T-96

Used for testing Crushed Rock, Crushed Slag, Crushed and Uncrushed Gravel for Resistance to Abrasion.

The machine consists of a hollow cylinder mounted horizontally on a study frame on Pillow block bearings. There is an opening which can be closed with a dust tight cover to facilitate charging and discharging the drum with the material under test. A detachable shelf which extends throughout the inside length of the drum which catches the abrasive charge and does not allow it to fall on the cover. The drum is rotated by an electric motor through a heavy reduction gear at a speed of 30--33 R.P.M. A revolution counter is fitted to the frame. A tray is supplied for collection of the material at the end of the test. Complete with Abrasive Charge consisting of a set of Twelve hardened steel balls, approximately 48mm dia. Suitable for operation on 440 V, 3 Phase, 50 cycles, A.C. Supply.

Used for testing Crushed Rock, Crushed Slag, Crushed and Uncrushed Gravel for Resistance to Abrasion.

The machine consists of a hollow cylinder mounted horizontally on a study frame on Pillow block bearings. There is an opening which can be closed with a dust tight cover to facilitate charging and discharging the drum with the material under test. A detachable shelf which extends throughout the inside length of the drum which catches the abrasive charge and does not allow it to fall on the cover. The drum is rotated by an electric motor through a heavy reduction gear at a speed of 30--33 R.P.M. A revolution counter is fitted to the frame. A tray is supplied for collection of the material at the end of the test. Complete with Abrasive Charge consisting of a set of Twelve hardened steel balls, approximately 48mm dia. Suitable for operation on 440 V, 3 Phase, 50 cycles, A.C. Supply.

Digital Los Angles Abrasion Testing Machine

EN 1097-2, 12697-17, 13450; ASTM C131, C535; AASHTO T96

The machine consists of an electronic control unit and a rolled steel drum having an inside diameter of 711 mm and internal length of 508 mm. The drum is rotated at a speed of 31-33 r.p.m. The internal shelf provided with the machine confirms to ASTM, AASHTO and EN standards. The machine is equipped with an automatic counter, when the preset revolution count is reached, the machine will stop automatically.

The drum is equipped with an interlock device which allows the operator to lock the drum into position for easy loading/unloading of the sample. Power consumption: 750 W

The machine consists of an electronic control unit and a rolled steel drum having an inside diameter of 711 mm and internal length of 508 mm. The drum is rotated at a speed of 31-33 r.p.m. The internal shelf provided with the machine confirms to ASTM, AASHTO and EN standards. The machine is equipped with an automatic counter, when the preset revolution count is reached, the machine will stop automatically.

The drum is equipped with an interlock device which allows the operator to lock the drum into position for easy loading/unloading of the sample. Power consumption: 750 W

Dorry Abrasion Testing Machine

BS 812

For Testing Aggregates for Resistance to Abrasion.

It consists of a disc rotating about a shaft connected to a reduction gear box coupled to a motor. The disc rotates at 28-30 RPM. Under the rotating disc is a tray with an outlet to facilitate the removal of sand. Two Conical Hoppers are mounted on a bracket fixed to the circular tray. An arrangement is made for start and stop the flow of sand. Two containers with weights are supplied to keep the specimens pressed against the rotating disc. Suitable for operation on 220 V, 50 cycles, A.C. Supply.

For Testing Aggregates for Resistance to Abrasion.

It consists of a disc rotating about a shaft connected to a reduction gear box coupled to a motor. The disc rotates at 28-30 RPM. Under the rotating disc is a tray with an outlet to facilitate the removal of sand. Two Conical Hoppers are mounted on a bracket fixed to the circular tray. An arrangement is made for start and stop the flow of sand. Two containers with weights are supplied to keep the specimens pressed against the rotating disc. Suitable for operation on 220 V, 50 cycles, A.C. Supply.

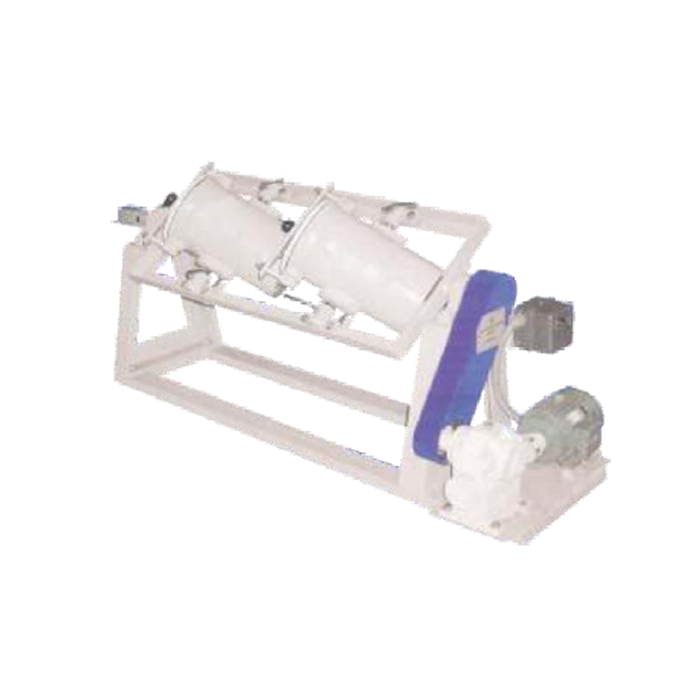

Devel Attrition Tester

ASTM D2-33 & IS 2386 (PART IV)

For The Determination of Resistance of Aggregates to Wear by Abrasion.

It consists of two hollow cylinders closed at one end and provided with Fitting covers at the either end. These cylinders are mounted an a shaft at angle of 300 with the axis of rotation of the shaft. The shaft rotates at 30-33 RPM. Through a reduction gear operated by a motor and is provided with a revolution counter. Complete with Abrasive Charge consisting of 12 Nos. Hardened steel Balls of 48mm dia. Suitable for operation on 440 Volts, Three Phase, 50 Cycles, A.C. supply.

Note :

Option of Digital Preset Counter can be provided at an Extra Cost.

For The Determination of Resistance of Aggregates to Wear by Abrasion.

It consists of two hollow cylinders closed at one end and provided with Fitting covers at the either end. These cylinders are mounted an a shaft at angle of 300 with the axis of rotation of the shaft. The shaft rotates at 30-33 RPM. Through a reduction gear operated by a motor and is provided with a revolution counter. Complete with Abrasive Charge consisting of 12 Nos. Hardened steel Balls of 48mm dia. Suitable for operation on 440 Volts, Three Phase, 50 Cycles, A.C. supply.

Note :

Option of Digital Preset Counter can be provided at an Extra Cost.